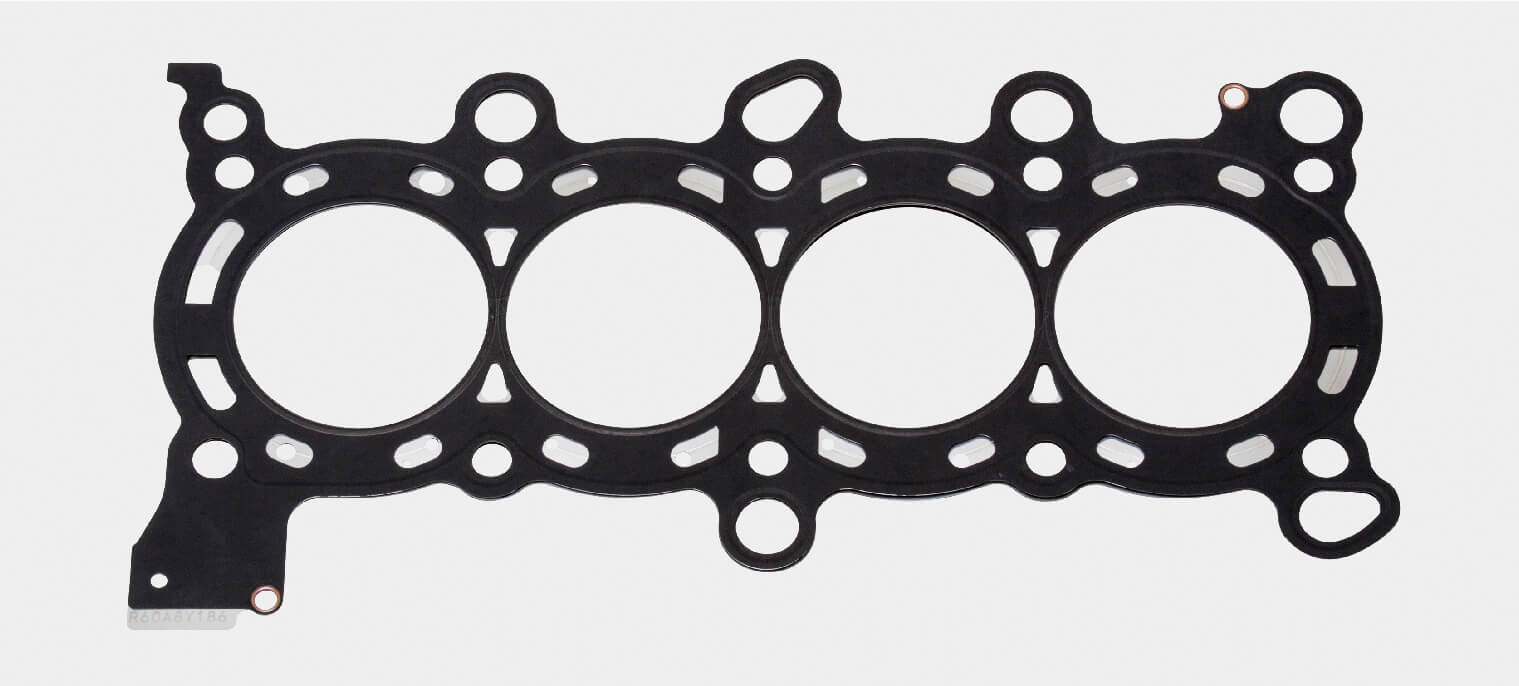

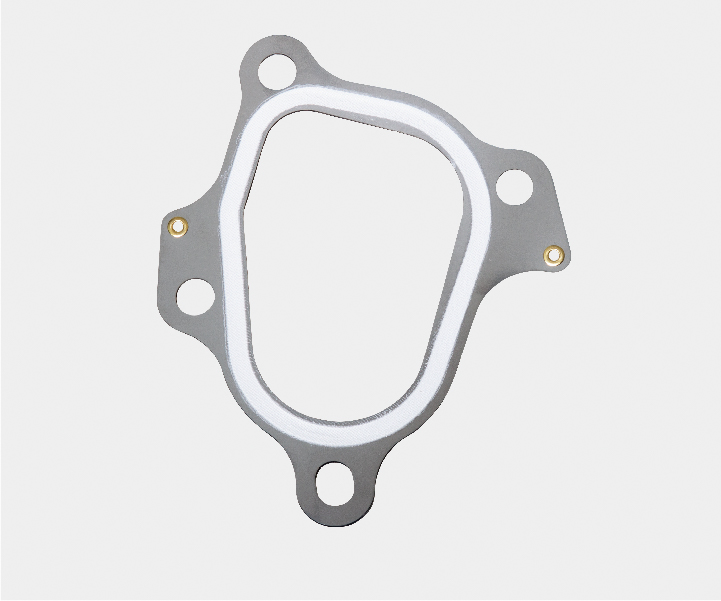

Generally, these are products made by punching stainless steel with a thin coating of NBR or FKM rubber on both sides. They are suitable for use in high-temperature and high-pressure environments such as engines, exhaust systems, and fuel supply systems, as they are less prone to deformation or deterioration and ensure good sealing and durability. By applying bead processing, they become gaskets that combine the ability to follow load changes with the excellent sealing properties of the rubber layer.

(FKM Post Coat)

(LCP-1 Spray)

(NBR RCM)

(Composit Graphite)

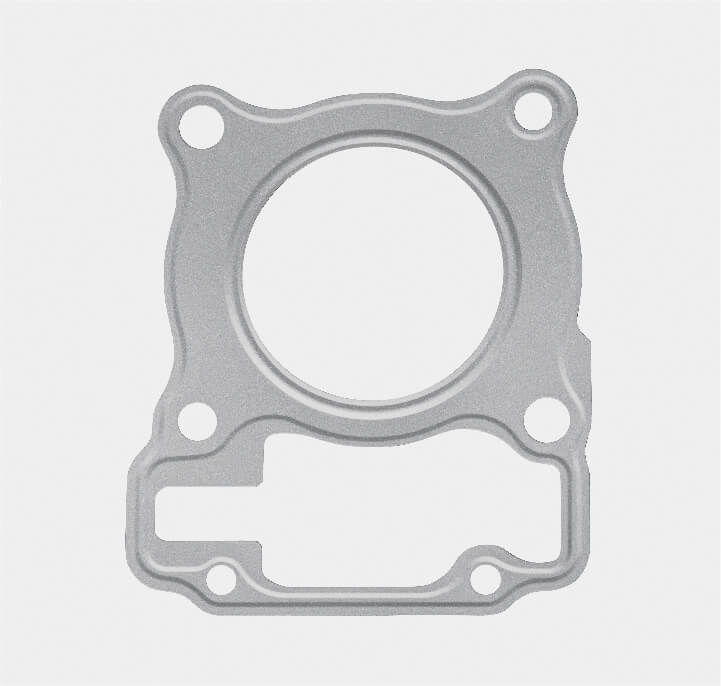

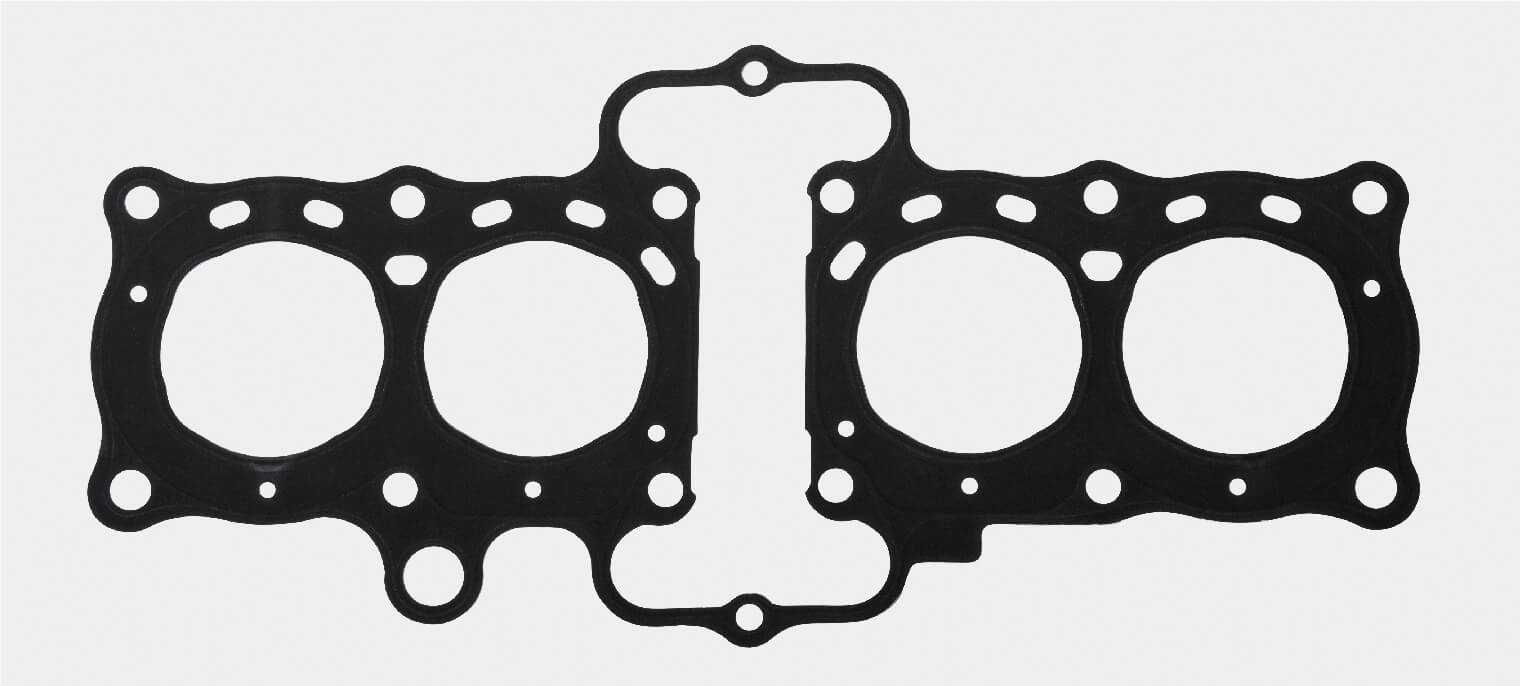

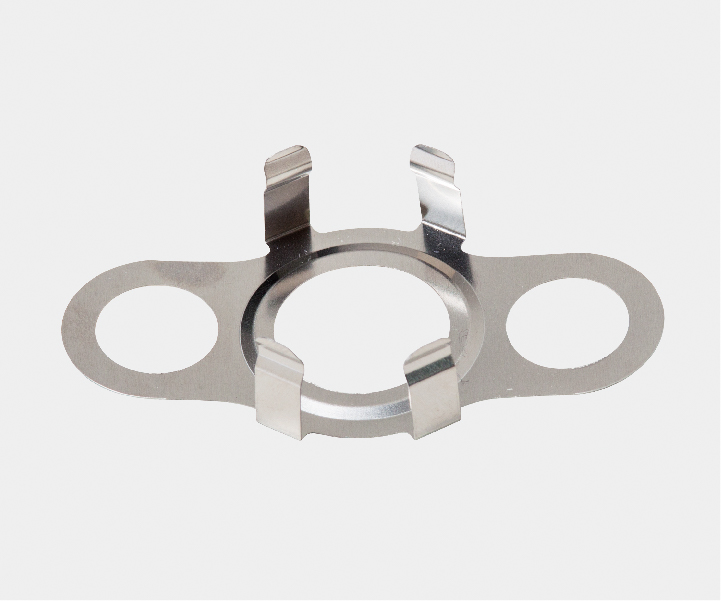

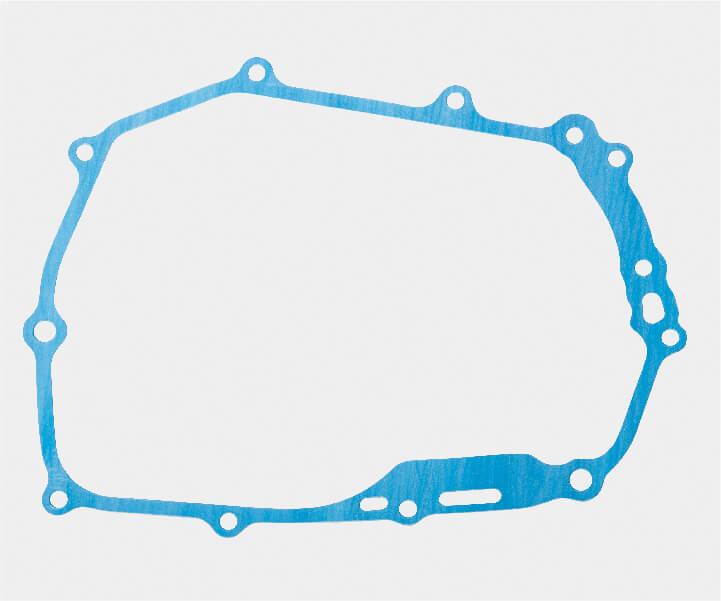

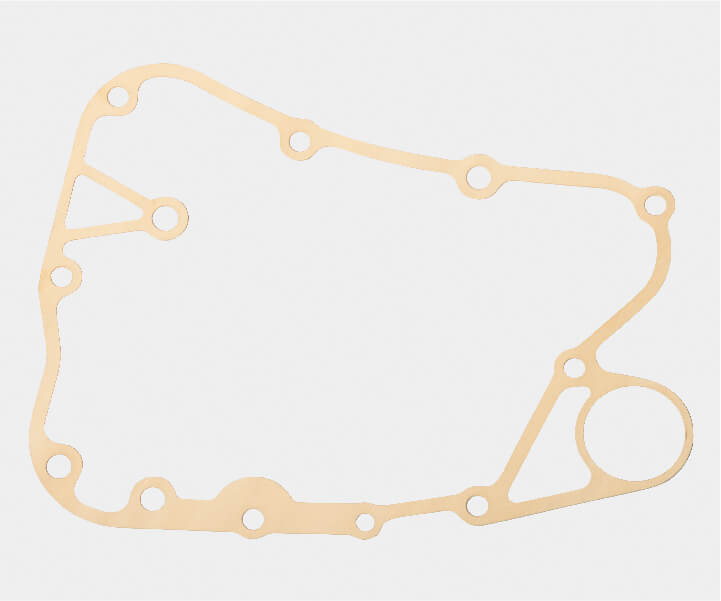

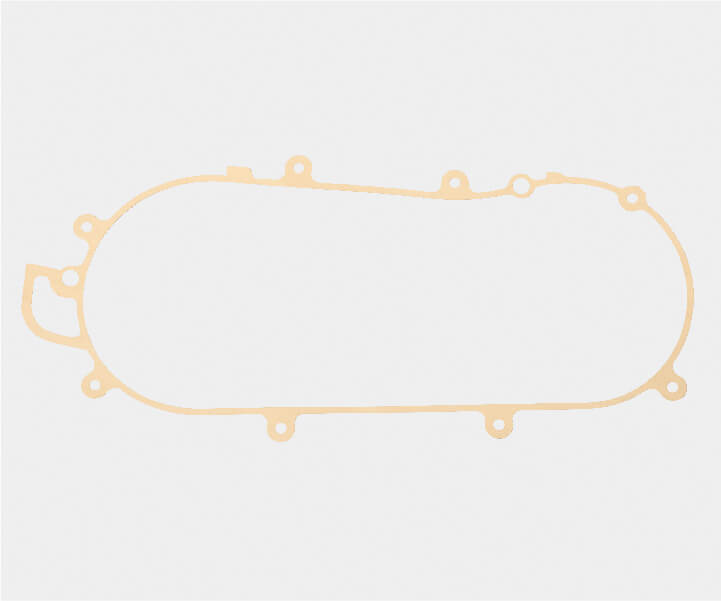

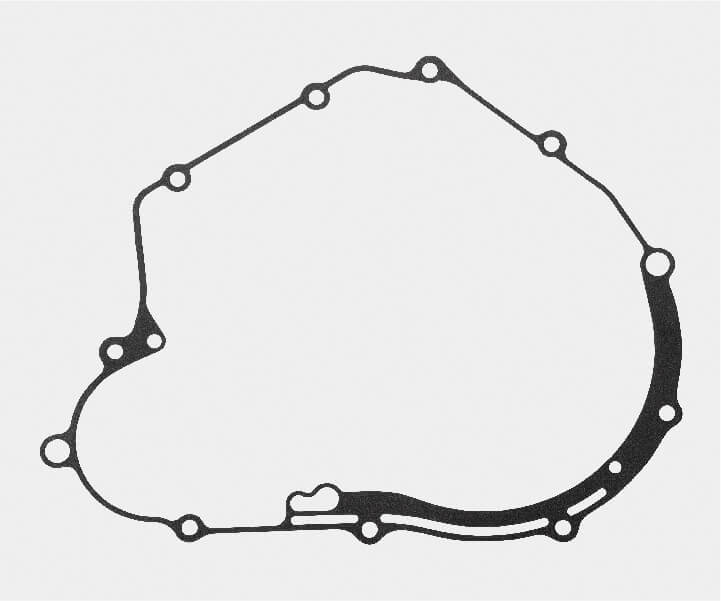

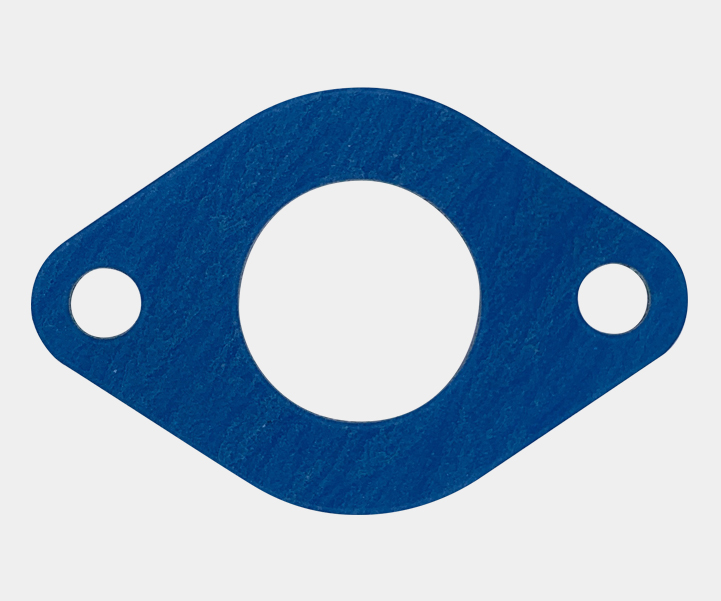

These are products made by punching joint sheet material or material made of thin steel plate coated with foamed rubber on both sides. They are resistant to high temperatures and pressure changes, and are flexible and have good sealing properties, so they are used for joining parts such as engines, transmissions, and crankcases.

(Joint Sheet)

(Joint Sheet)

(Joint Sheet)

(Foamed Rubber)

(Aluminum)

(Copper)

(Fiber Material)

(Fiber Material)